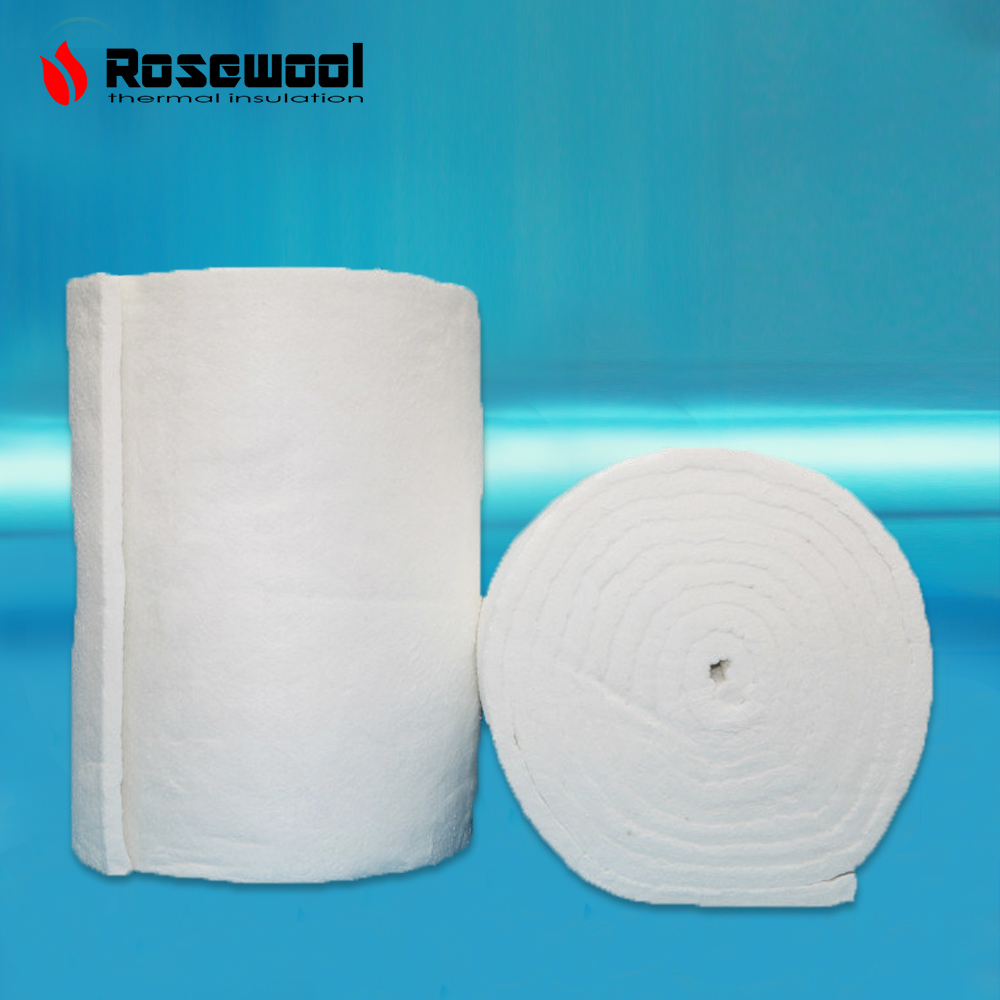

Lowes Fire Proof Insulation 1260c ceramic fiber blanket

Details

Product description :

Ceramic fiber blanket ,also named as fire resistant blanket ,is one of the main insulation product. It is mainly used in the furnace for heat insulation and thermal insulation in 1100℃-1600℃ (2012℉-2912℉). Through by blowing and spinning techniques ,these products have superior insulation performance, excellent flexibility.

Feature :

Fireproof :

ceramic fiber blanket is the defender of furnace , long-term working temperature is arrived 1000-1600 degrees celsius.

heat preservation:

Ceramic fiber material at an average temperature of 200 ℃, the thermal conductivity of less than 0.06 W / mk, an average of 400 ℃ less than 0.10 W / mk, about 1/8 of the lightweight heat-resistant design materials, about 1/10 of the light brick)

Excellent Thermal Shock :

Fireproof fiber blanket has good thermal shock resistance, after a sharp change of temperature will not crush fracture is still intact, has good fire insulation performance

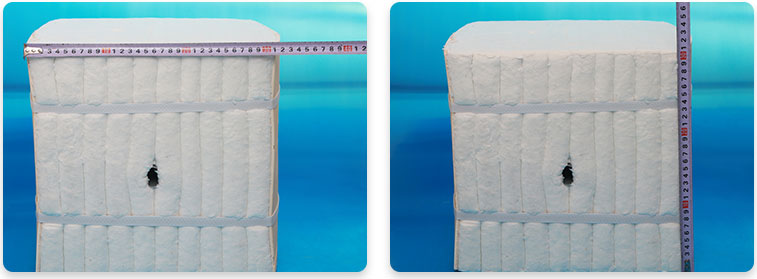

Double needle:

Fiber blanket double needle, texture clear, uniform distribution, has good tensile strength, easy to install.

Environmental Protects :

We use selected natural raw stone as raw material, non-asbestos products without pollution.

Application:

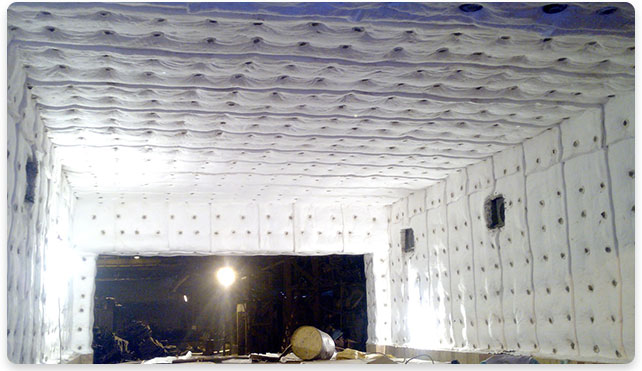

Kiln/furnace lining :

All kinds of kiln lining, such as: the tunnel kiln, the kiln and glass furnace, boiler ,furnace door seal ,heat shields, field stress relieving, steam and gas turbine insulation ect. Very suitable for as a furnace heat preservation and heat insulation material.

Pipe insulation : After double needle technology has greatly increased the degree of fiber weaving, delamination resistance, tensile strength and surface roughness, easy installation, operation is flexible and convenient,is a heat pipe heat preservation and heat insulation material.

Household stoves :

Heat insulation blanket is always used to Pizza oven and fireplace and so on .

The ceramic fiber module of raw materials :

Ceramic fiber blankets can be made into ceramic fiber modules by folding and processing

Packing and shipping :

Packing Details : 1.Plastic bag inside ,woven bag outside. 2 rolls/ bag. 620 rolls/1*40HQ.

2. Plastic bag inside, carton outside. 1 roll/carton. 525 cartons/1*40 HQ

3. Wooden pallet. 20 cartons/pallet, 21 pallet/1*40 HQ.

4. As customer's requirement, OEM is accepted.

Shipping :

1. shipping & packing details will according to clients' requirements to design.

2. Before delivery, we will have three inspection lines: A,Check B,Test C,Inspect ,taking photos for you .

3. Our common exporting package is made of five layers of corrugated paper, With a strong waterproof performance it is suited to long-distance shipment .